- PRODUCTS

- SOLUTION

- SERVICE

- NEWS

- ABOUT US

To connect a fuel tank semitrailer, align the kingpin of the semitrailer with the tractor's fifth wheel, ensuring a secure latch. Perform a pull test to confirm the connection is secure

Before connecting the fuel tank semitrailer, make sure that all safety checks have been executed. Ensure the operational capacity of both the tractor and the semitrailer. Previous to the coupling, conduct visual inspection of both, tractor s fifth wheel and semitrailer s kingpin for wear and damage. Ensure that both, the tractor s brakes and semitrailer s brakes function in all levels of application in order to ensure the lack of movement.

Ensure that the tractor is directly in front of the semitrailer. A lack of alignment can cause complications during the connection. Guide marks both at the tractor and the semitrailer assist in aligning the tractor’s fifth wheel to the trailer’s kingpin. It is recommended to adjust the tractor s position multiple times with the semitrailer to gain a perfect alignment.

Slowly reverse the tractor, so the fifth wheel ass will engage with the kingpin. While doing so, listen to an audible click from the kingpin, meaning that the connection has been achieved. Another necessary visul training is to see that the locking mechanism is in full contact at the cross assembly. After the connection, perform the tug test by driving the tractor slowly in a small distance. This test ensures that the kingpin is in lock and full connection with the fifth wheel.

Examine

After the connection, make sure that all safety checks have been conducted. Through visual inspection ensure that all of electrical connections and air lines are linked securely and not damaged. Test the functionality of trailer lights, meaning brake lights, turn signals as well as tail lights and air brakes. Furthermore, document the case as to C.V.O.R. mandatory safety requirements.

Finally, ensure that the height of the trailer is suitable to coupling by adjusting the landing gear. The semitrailer should be level with the tractor shape to prevent pressure of the frame. Make sure that all of the locking pins are in full contact as well as that the landing gear is off the surface of the road.

The proper alignment of the tractor to a fuel tank semitrailer is essential for a secure connection. Initially, the tractor must be located straight behind the trailer, as this will prevent the lateral load to the kingpin and fifth wheel while coupling. To ascertain the vehicle’s position, it is crucial to perform a visual check and then to adjust the approach to the fuel tank semitrailer before making the actual connection.

Perform a visual check from a distance to make sure that the tractor is in line with the centerline of the semitrailer. The kingpin and the fifth wheel should fit perfectly without you making any forceful adjustments. Besides, in optimal conditions, you will be able to follow the lines painted on the ground or any other marks that will indicate the proper placement of the tractor.

Therefore, on your way to the semitrailer, only slight adjustments of steering are required. It is important to retain the linear course towards the kingpin, as the precision of the approach is a key factor for a safe and simple connection. Additionally, it is valid to have a spotter assistant outside the tractor who will give you movement directions using manual signs or a radio.

Furthermore, when you are close to the trailer, stop the tractor and make a final visual check by the side to test if the fifth wheel is right in front of the kingpin. It is essential to make any minor adjustments at this point. Therefore, at the final stage, you ensured that you are at an optimum parallel position to the trailer, and no forced coupling will be conducted.

Thus, now you are ready to proceed by slowly backing up the tractor into the semitrailer. The alignment was correct if the kingpin easily fits into the fifth wheel without any hesitation and produced a locking sound. Undoubtedly, do not forget to check the gear to establish that you did not forget to place the tractor in neutral.

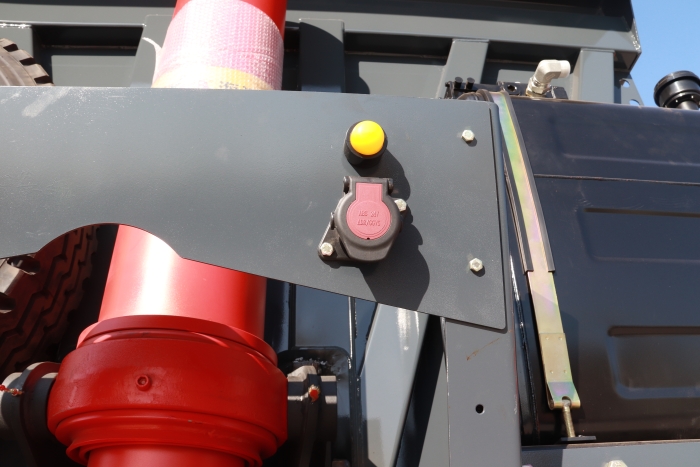

The locking connection device is a safety attribute that is necessary to take the fuel tank semitrailer in tow to the tractor. This device includes two basic elements: the fifth wheel and the adjustable rod. The former is mounted on the chassis frame, and the latter is on the semitrailer. The fifth wheel’s locking mechanism interacts with the kingpin of the semitrailer. It is crucial for the safe transportation of overloads and imposes obligatory operating rules.

To make final it ready for taking the semitrailer in tow, you need to conduct some basic procedures. First, you need to inspect the condition of the turntable’s locking mechanism. Check if there is no debris or damage, and there are no signs of excessive wear. In addition, the locking jaws of the fifth wheel should be free of rust and dirt and well greased. In the case of wear, the jaws have to be replaced. This kind of maintenance should be done regularly, since it speeds degradation, and the lockjaw should also be cleaned and greased to ensure smooth movement.

The connection process is rather simple. You should just back the tractor up to the semitrailer until the fifth wheel slide under the frame and touch the semitrailer’s built-in guides. While the kingpin is sliding into the bushing, the turning of the fifth wheel should be heard with a distinctive click. If there is no sound, it necessarily means that the pin is not locked in place and it is inadvisable to take the lowmead. If you hear the click, perform the visual confirmation and check the lockjaw through a special window or a flashlight shining out the lower back of the fifth wheel. The final test is the pullman. Incrementally start sliding the coupling forward in order to provide enough time down to gradually stop the tractor if the pin has been unsuccefully locked.

After connecting a fuel tank semitrailer to a tractor, it is vital to perform thorough security checks and confirmations to guarantee that not only the connection is secure but also safe for any manipulations. As a result, the following steps should be taken, relying on visual and physical inspections, verification of safety devices, functional testing of connected systems, and documentation and compliance checks.

Inspect the site of the connection visually, examining that the kingpin is properly hooked to the fifth wheel. Perform physical examination of the intensity and the amount of inserted locking pins.

Verify that all safety devices associated with connection to the kingpin are engaged. It includes examining whether the safety latch works properly and all secondary locks and failsafe mechanisms are correctly set.

Test all systems that require stable and secure connection between the truck and the semitrailer. It includes examining electrical systems required for lighting and brakes, and air systems connected to braking systems of both trailer and tractor. Test each system to ensure that it is both responsive and operational.

Complete the checks required to verify that the connection is secure. Ensure that all safety standards are met, and all documentation for compliance is complete. Not only it is important for security standards but for the liability associated with any potential accident.

To ensure the safety of transportation, it is crucial to test the stability of the connection between the tractor and the fuel tank semitrailer. Below are several specific tests to check the security of connection.

The static tug test should be implemented initially. The tractor’s engine should be engaged, and the speed should be gently advanced while the semitrailer’s brakes are activated. This is effective to check whether the connection is secure to the tractor’s power. The test is successful when no shift occurs, and no noise indicates that the connection is getting loose.

The dynamic movement test can be implemented once more checks are performed. The interconnected rig should be driven at a low speed in a secure, isolated space to ensure safety. Several turns and slopes need to be gently driven to ensure the stability of the connection under varying amounts of forces. By paying close attention, the driver should be mindful of any noise indicating a shift of the connection.

One of the ways to test the stability of the connection of the semitrailer is by operating the brake system. The brakes of the semitrailer should be installed to allow simultaneous engagement of the tractor and the semitrailer for safe driving. A section of the test should be the test of the semitrailer brakes, which should allow no delay from the tractor’s brakes. This is essential to maintain safety and ensure the interconnected rig is not shifted. Thus, successful tests should conclude without any connection problems.

The stability test of the connection would not be complete without simulating emergency maneuvers such as driving at higher speed and making rapid lane changes or braking, for which no shift or inappropriate connection movement should be present.