- PRODUCTS

- SOLUTION

- SERVICE

- NEWS

- ABOUT US

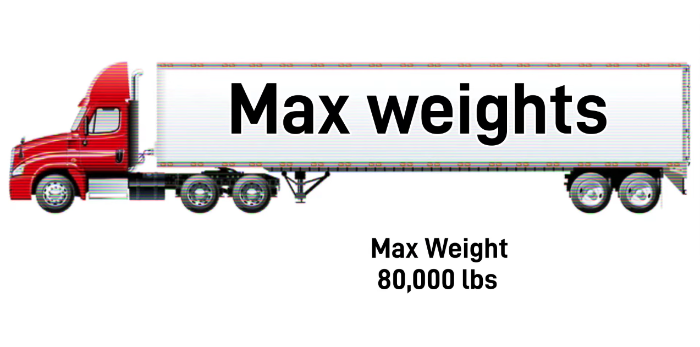

There may be a question about why a 53-foot semi trailer is chosen for weight distribution instead of more common 20-foot or 40-foot semi trailers. The answer is that while a 53-foot semi trailer is one of the possible options to carry a lot of cargo, it is one of the very few options to carry a maximum weight with the total weight.

Moreover, its semi trailers which employ a maximum gross vehicle weight of 80,000 pounds that includes the weight of the tugger,semi trailer, and cargo. As a result, maximizing weight distribution is easier with a 53-foot semi trailer. At the same time, weight distribution on a 20-foot/40-foot semi trailer can also be achieved using a 53-foot distribution strategy.

If you understand the weight distribution between the tugger and semi trailer, and can calculate it accurately, you will be able to keep the maximum cargo weight within the legal limit for a 53-foot semi-trailer, avoid fines, and transport safely. You can do this by following these steps:

Determine Tare Weight:

First determine the tare weight, which is the non-moving weight of the tugger and semi trailer. Typically, a 53-foot trailer has a tare weight of 10,000-15,000 pounds, while the trailer's tare weight is usually in the 15,000 – 25,000 pound range.

Calculate Total Tare Weight:

Add the empty weights of the tugger and semi trailer. For example, if the trailer weighs 15,000 pounds, and tractor’s weight is 25,000 pounds, then the total tare weight is 40,000 pounds.

Subtract from GVW:

Subtract tare weight from the GVW limit, i.e. 80,000 pounds. Using the example above, this calculation will be the following: 80,000 pounds – 40,000 pounds = 40,000 pounds. It means that the maximum cargo weight is approximately 40,000 pounds. Naturally, it is an ideal number, and the actual number will vary under normal conditions. However, in this paper, it will serve as a reference standard.

Axle weight limits:

Steering axle: usually up to 12,000 pounds.

Drive axle: up to 34,000 pounds.

Trailer axle: up to 34,000 pounds.

After calculating these weights, you must also ensure that your semi trailer is loaded within the legal limit to avoid accidents caused by uneven distribution of cargo during transportation, which may cause the axle weight to be exceeded and the stability of operation to be lost.

Next is the core of how to distribute weight, that is to develop a strategy in advance. Here, we first consider it from the perspective of cargo placement. Correct cargo placement plays a decisive role in the overall safety and efficient weight distribution of the semi-trailer. According to the conventional idea, the weight is evenly distributed to ensure even weight distribution and prevent axle overload, but this idea is often the most likely to make the axle unable to withstand it, because the weight of the cargo is mostly uneven, and considering the special nature of some cargo, how to place the cargo becomes the key point.

Strategic cargo placement tips:

From the perspective of load priority planning, place the heaviest items (such as machinery or large pallets) directly above the axles of the semi trailer. Then distribute medium-weight items to the front and rear to ensure an even load on the length of the trailer.

Keep a low center of gravity in the overall trend and keep the heaviest items low on the semi trailer deck to lower the center of gravity and improve stability.

Cargo loading should be from front to back, that is, starting from the front of the semi trailer and moving back. This method ensures a balanced load and better control of weight distribution, and can be staggered vertically and horizontally according to the weight of the cargo, so that everything is stuck and there is no worry of shaking.

In addition, make sure there is no overhang outside the axle, because you want to ensure that the heavy objects are not hanging on the rear axle, otherwise it may cause imbalance and handling problems.

If the placement of strategic cargo is the first layer of protection, then fixed load is the second layer of protection. Because fixed cargo can ensure that the cargo will not shift during transportation, in principle, it stabilizes the center of gravity of the semi trailer, so as to ensure a safe and stable driving process.

Of course, fixed load is not as meticulous as strategic cargo placement. The only thing to pay attention to is that the material of the strapping should be good to ensure that it does not break in the middle. In addition, fixed load mainly divides the layout of cargo placement into blocks, and places the load bars horizontally on the semi trailer to fix the stacked items and prevent them from moving. The second is to bind larger and heavier cargo twice to ensure that it will not move during transportation due to the inertia caused by the movement of the semi trailer. Here you can also tie more straps to evenly distribute the fixing force and prevent the straps from breaking.

Before any journey, a thorough pre-haul inspection is necessary to ensure that the load is secure and evenly distributed. Through these inspections, it is possible to see which part of the cargo is not securely fastened or affects the weight distribution. In addition, these steps may allow people to comply with weight regulations when driving on the road.

The following steps need to be performed:

Weigh the axles: Take a scale and find out the weight on each axle. Make sure the weight is within the legal limit for each specific axle. Check if the load is evenly distributed, by measuring, make sure that the released weight is evenly distributed across the length and width of the semi trailer.

Verify Securing: Check if everything is securely mounted, especially the load bars and straps. Check if there have been any internal changes to the way the cargo is placed and confirm that it is secure, and finally, an inspection of the cargo and semi-trailer as a whole.

In addition to the pre-haul inspection, it is important to stop and check the load regularly and make any necessary adjustments. The reason for this is that when hauling long distances or encountering cargo and semi trailer problems, you may be forced to redistribute by properly securing misplaced cargo or changing the seating position of some cargo.

Check regularly: Stop the vehicle every once in a while and recheck all straps and load bars to make sure none of them have come loose. If there have been any changes in the cargo, make corrections and rebalance the load. This may even require replacing some items or tightening the straps.

Weight distribution monitoring: Reweigh the axles to make sure the overall weight is there, then repeat the above process to ensure a safe and stable journey ahead.